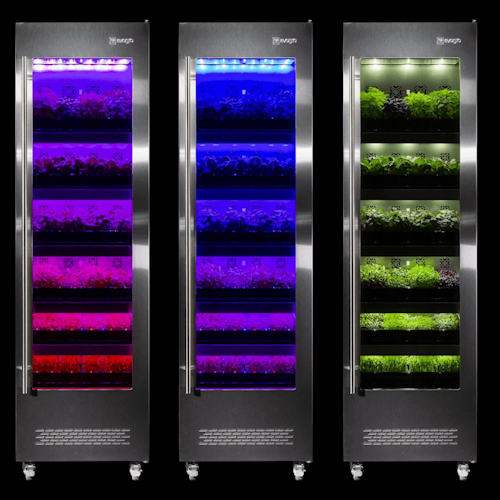

Case Study: Hydroponic Plant Growing Management System for Chefs

Indoor Agriculture Innovation – EvoGro Plant Growing System

The Challenge

EvoGro developed a smart indoor agriculture system specifically designed for chefs and professional kitchens. At first, their model included LED lighting, environmental sensors, climate controls, and internet connectivity to support the growth of fresh herbs and microgreens. However, since the system relied on off-the-shelf components, it was difficult to assemble, less reliable, and hard to scale for commercial use. Therefore, EvoGro recognised the need for expert support to improve the design. As a result, they turned to RVL to help transform their innovative concept into a high-quality, efficient, and production-ready product. In the end, the goal was to meet the rising demand in the fast-growing indoor agriculture market.

Concept Refinement

EvoGro came to RVL with a working prototype and a clear objective: simplify the system and improve its reliability without compromising on functionality. The product drew on hydroponic and indoor agriculture principles, but the engineering required refinement to support efficient manufacturing. RVL worked closely with the EvoGro team to fully understand the technical and operational goals. Through in-depth collaboration, RVL helped reshape the concept into a more practical, cost-effective, and production-ready version. The team preserved the core vision while adapting the design to be scalable for the future.

The Solution

RVL engineers proposed a multi-step improvement plan, and EvoGro reviewed and approved it. The team then designed a custom PCB to replace the tangle of off-the-shelf parts. This reduced complexity, improved reliability, and aligned with the performance needs of modern indoor agriculture systems. The bespoke solution enhanced system integration while supporting the environmental monitoring and automation features essential to plant growth.

The team manufactured and tested prototypes through a refinement process, ensuring the final design met all functional and aesthetic expectations. Once validated, the product moved into production with the reliability and build quality necessary for demanding commercial kitchens.

The Outcome

Today, top chefs, hotels, and food businesses across the UK are using EvoGro’s advanced indoor agriculture technology. By reducing assembly time, increasing reliability, and delivering excellent performance, the EvoGro system is redefining how fresh produce is grown at the point of use.

Project Highlights

-

Concept refinement for indoor agriculture application

-

Custom PCB design and system integration

-

Prototyping, testing, and manufacturing efficiency

Learn more: www.evogro.com