Technical Capabilities

Technical Capabilities

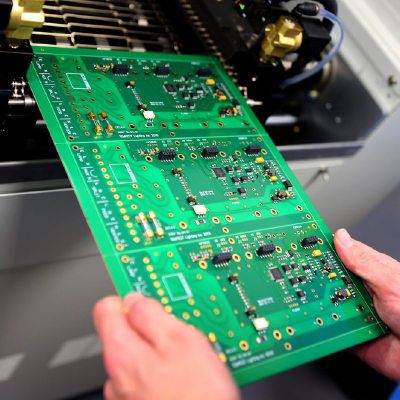

RVL’s technical capabilities have developed over time according to changing customer requirements. For example, perhaps you are looking for surface mount capability? Our MY300-DX pick-and-place machine (Mycronic) can place components from 01005 size up to more than 50mm square QFP, including uBGA sizes with high speed and accuracy. With spaces up to 224 feeders and built-in fast set-up times, our production capacity has been doubled since the installation of this equipment. If required, for ultimate quality this machine can test and check every single resistor and capacitor before placement.

We can convert through-hole boards to surface mount, as this reduces board size and sometimes end product size. As a consequence, we can improve your electronics manufacturing costs, while creating a repeatable quality standard with no variance, thereby ensuring better availability of parts.

In order to provide a complete end-to-end service, RVL can also provide complementary services. With choices of Heller multi-stage reflow or IBL vapour phase soldering for dense or high mix type boards, we have the complete surface mount assembly solution for all your low to medium surface mount needs. In addition, we often assist clients with cable and harness wiring, electro-mechanical assembly and full box builds.