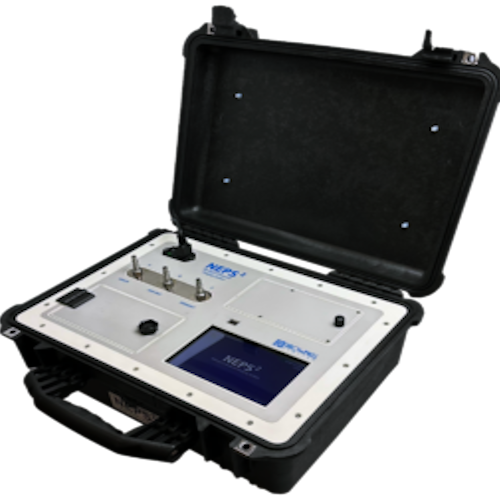

Case Study: Optimisation of a Dry Gas Purging Control System

Completing, Enhancing, and Supporting a Mission-Critical Control System

RVL partnered with Brownell on the NEPS 2 project, providing engineering expertise to complete, enhance, and support a complex electronic control system originally started prior to RVL’s involvement.

The project demanded rapid onboarding, technical clarity, and a delivery-focused approach to meet a challenging schedule while ensuring long-term product stability.

Rapid Project Takeover and Completion

When RVL joined the project, approximately half of the development was already complete. RVL carried out a detailed technical review of the existing electronics and firmware to identify risks, validate design decisions, and establish a clear path to completion.

This early assessment enabled the remaining development to be completed efficiently and with confidence.

Electronics, Firmware, and Software Architecture

RVL completed the electronics and firmware development for NEPS 2, delivering a robust and production-ready control system.

The software architecture utilises FreeRTOS for real-time task management, combined with TouchGFX to deliver a responsive and intuitive touch-screen user interface. The core of the system is based on an EDT display and microprocessor module, selected to provide an integrated, reliable platform for graphics, processing, and system control.

RVL also designed all bespoke supporting electronics around this core module, ensuring seamless integration and system-level reliability.

Ongoing Software Development and Feature Enhancement

Following initial delivery, RVL continues to work closely with Brownell to extend the NEPS 2 software, adding new features and refinements as operational requirements evolve.

This ongoing development approach allows the platform to grow over time without the need for disruptive hardware changes.

In-House Manufacturing and Long-Term Support

RVL manufactures all bespoke electronics for the NEPS 2 system in-house, providing consistent build quality, traceability, and continuity of supply.

Direct involvement in both design and manufacture allows RVL to respond quickly to updates, improvements, and production demands throughout the product lifecycle.

Collaborative Partnership and Future Projects

The NEPS 2 project established a strong, collaborative working relationship between RVL and Brownell, supported by regular communication and a shared focus on delivery. This approach ensured rapid decision-making and effective progress, even against an aggressive schedule.

With NEPS 2 now in service and continuing to evolve, RVL and Brownell are actively exploring further projects to tackle in the coming year.

Outcome

By integrating seamlessly into an ongoing project, completing development, and providing continued software enhancement and manufacturing support, RVL has delivered a robust, scalable solution for Brownell. The NEPS 2 platform continues to evolve, underpinned by a long-term engineering partnership.